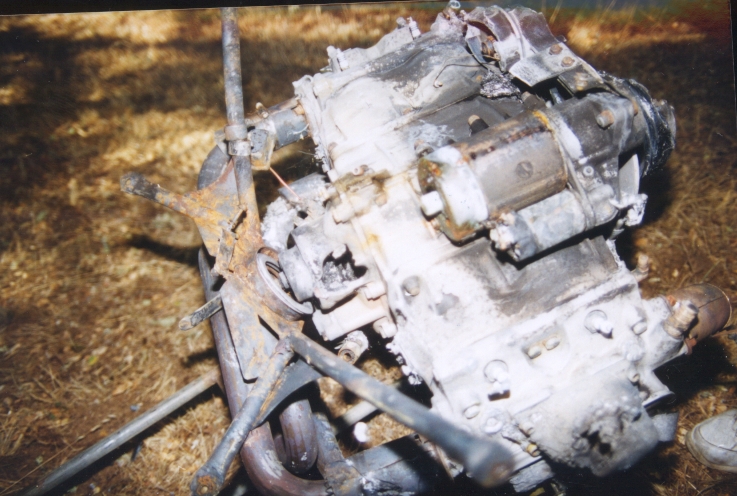

Jim Dohrman

allowed his tail rotor drive belts to run too loose

and knew it but he let it go a bit too long. He lost

his tail rotor belt while flying with his wife in

this ship and did an auto into this stand of oak trees.

He then was medevaced to a local hospital by helicopter.

He is now flying Medevac helicopters with much of

his required helicopter flight time gained in this

Rotorway helicopter. It is now in the process of being

rebuilt.

I would like

to point out that even though Jim's Rotorway fell

through the canopy of trees to the ground, the crashworthiness

of this kit helicopter undoubtedly saved the lives

of the occupants and prevented serious injuries.

The tail

rotor belt system on the pre-Talon Rotorway helicopters

is reliable when properly tensioned, inspected, and

maintained.